JG Series Vacuum Filter

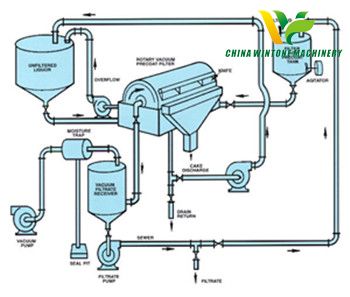

JG series vacuum filter is extensively used in starch, medicine food stuff, chemistry, metallurgy, mineral industry, etc for solid and liquid separation, especially for corn starch for dehydration and separation of solids from liquids of material with small grain, not easy to precipitate and being sticky.

Advantages of vacuum filter: this equipment functions well, low for energy consumption easy of maintenance and repair.

This machine is a continuous vacuum filter. It is used in filtering serous material in the process of extracting phosphoric acid so as to separate phosphoric acid from ardealite.

The best characters of vacuum filter are multistage counter flow washing, high recovery ratio, stable running, low maintenance coat. Performance is especially good when separating serous material with high-density solid, big particle, high concentration.While some fan-blade filter-pans rotate horizontally, the process of feeding, washing, dehydration, and discharging dregs, etc, can be completed continuously.

Main Specifications and Technical Parameters of vacuum filter:

|

Type |

Filter Area |

Vacuum Degree Mpa |

Concentration of fed Material |

Dryness of Discharged Material |

Daily Output T/ |

|

JG-30 |

30 |

0.4-0.8 |

11-13 |

63% |

0.6-0.8 |

|

JG-35 |

35 |

0.4-0.8 |

11-13 |

63% |

0.6-0.8 |

|

JG-40 |

40 |

0.4-0.8 |

11-13 |

63% |

0.6-0.8 |

|

JG-45 |

45 |

0.4-0.8 |

11-13 |

63% |

0.6-0.8 |

|

JG-50 |

50 |

0.4-0.8 |

11-13 |

63% |

0.6-0.8 |

|

JG-60 |

60 |

0.4-0.8 |

11-13 |

63% |

0.6-0.8 |

|

JG-70 |

70 |

0.4-0.8 |

11-13 |

63% |

0.6-0.8 |